Want to talk about an OMFG! Look at the fist pic below, I removed the cover over the bulbs and the fist thing I see is black spots on the heat shields. Yep that is insulation burning off the wires feeding the cooling fans. I dont know the amps running to those fans but damn if an accident is not inevitable!

Pic 2 below

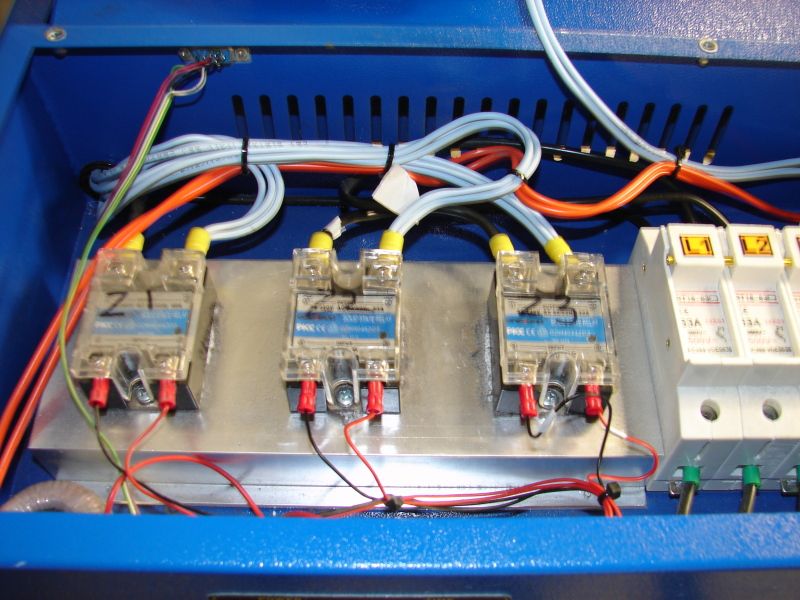

As you can see I traced the wires and marked each SSR to which zone it is. Surprisingly it is a ten bulb flash so the middle (zone2) is actually wired for four bulbs and the other two for 3 each.

Pic 3 below

I first purposely scorched a shirt so the pattern can be seen notice the last third of the shirt is where the major scorching starts. Also please keep in mind I have the flash shimmed 1/4" higher at the end in an attempt to control this.

Pic 4 below

First I swapped the control wires from zone 3 to zone 2 SSR respectively. Re scorched a shirt as you can see identical pattern.

Pic 5 below

I put the control wires back respectively, I then switched the output wires to the bulbs again with zone 2 and zone 3, I would have preferred zone 1 and zone 3 but the wires were to short. Anyways looking at the pic below I think tho it is not easy to discern that there is a difference, you guys can chime in and let me know.

To sum up it may appear to be a funky SSR ( I hope) The controller is definetaly ruled out I would say.

As for the wires burning up under the hood what the hell am I going to do about that? Brian what is the specs on these wires as in voltage and amps, is it dangerous?

Should I look for high temp wire to replace with or is there a high temp insulation I can wrap them in?

Re: Flash diagnosing update

How many volts?

Re: Flash diagnosing update

220vac. Just a little bite.

Owner/Operator of Middletownink

Re: Flash diagnosing update

Damn 220 at 1amp is a hell of a bite lol. Does that happen on all their flashes or am I just unlucky?

Re: Flash diagnosing update

Question ... can you post a pic of the burnt part of the black heat shielding ... I want to see if it melted beyond the sleeve ... below the black heat sleeve are high temperature wires <--- curious to see if the shield of those melted as well ???

Also ... we may have nothing more than a spotty SSR -but- we recently sent RockChick a bunch of new fans for one of her flashes ... they were a grainger swap out

Re: Flash diagnosing update

None of you equipment works right! LMFAO!!

Re: Flash diagnosing update

Interestingly your post does the same as well. So right back at ya.

Brandt

Graphic Disorder

http://www.graphicdisorder.com

Add us on facebook:

Brandt: http://www.facebook.com/graphicdisorder

Graphic Disorder:

http://www.facebook.graphicdisorder.com

Re: Flash diagnosing update

Oh please lets not muck this up anymore. This thread has nothing to do with Printex work not work robert blah blah blah, its for the fact that we are scorching the crap out of poly and blends. If I can get this resolved I will lose several levels of stress everytime I need to print a large image on poly.

Robert I will post a pic in a while but I just went and checked in one spot the heat shielding is almost all the way through, you can see some of the texture of the high heat wiring. I didn't realize that was only heat shielding I thought it was the actual wire insulation. Regardless I think it will be safer to move the wires to the out side.

Re: Flash diagnosing update

It's late in the day and boy wonder is surely out of meds

Re: Flash diagnosing update

Mike ... here is a link to the fans that were sent to RockChick ...

http://m.grainger.com/mobile/details/?R=4WT33

Verify if they are a correct swap out on your flash and WebgURL can get them enroute to you ... let us know ???

Re: Flash diagnosing update

No problem brother ... lets focus on getting this thing working ... please do me another favor and take a pic of the flash in the head where you normally have it height wise (with the table raised) just curious to see if what Brian is saying about flash distance being an issue as well

I am thinking with the new SSR in the zone with the 4 bulbs and the 2 working SSRs in the other 2 zones -plus- 2 new fans and some height/power intensity/timer tweaks we may have at least solved one problem ... lords knows we owe you plenty more solutions -buy- a small victory here would be great

Also ... we finally have some Prism II containers heading over from Poland and the first one is a 12 color so there should be some extra space in that 20 footer for some pieces parts :-)

Re: Flash diagnosing update

LOL ... how big is your squeegee? squeegee LOL

Re: Flash diagnosing update

Robert I took the pic of the burnt wiring as you can see you can just start to see the high heat insulation texture showing through. Oddly enough all that black shielding is melting if you touch it it sticks to your fingers all along the run. Probably not the right choice of material on Printex part.

I did get the SSR and I swapped it with zone 3 and did some scorch tests, I think but no where near sure that it is making a difference. The real test will be when we get a run going of poly and all the platens are piping hot. I would take another pic of the scorch but my camera is dead.

BTW a while back one of those fans crapped out on me, Brian pointed me in the right direction to swap it but I decided to monkey with the wires first to see what I needed to do to get it out and for some reason it started working again, nothing seemed loose but it is working.

Re: Flash diagnosing update

OOPs heres the pic

Pages